×

×

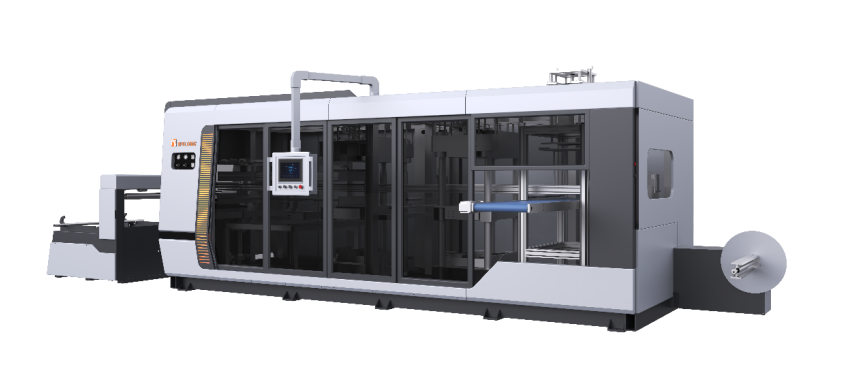

Thermoforming Machine

Thermoforming MachineMulti - station thermoforming is an advanced plastic - processing method. Heating plastic sheets, it shapes them in multiple stations simultaneously. This boosts efficiency and ensures high - precision results. It's widely used in packaging (for items like food containers), automotive (for interior parts), and consumer goods. As the plastics industry grows, multi - station thermoforming is vital for meeting demand for quality plastic products.

PRODUCTS

PRODUCTS

Plastic food boxes, egg trays,trays,

fruit boxes and other plastic products

Applicable materials:PP,PET,PVC,PS,PLA

Plastic food boxes, egg trays,

trays, fruit boxes and other plastic products

Applicable materials:PP,PET,PVC,PS,PLA

Plastic cups, lids, flower pots and

other products

Applicable materials:PP,PET,PVC,PS,PLA

Plastic products

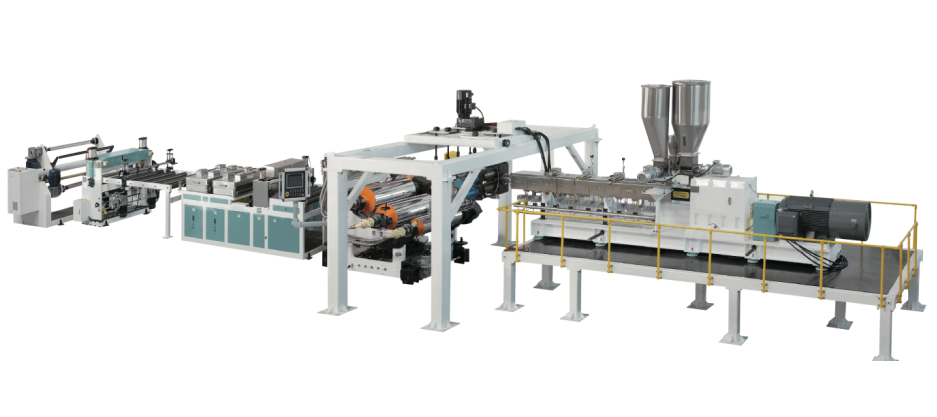

Plastic Sheet Extruder

Plastic Sheet ExtruderScope of application This sheet extruder adopts casting extrusion design, which is designed for highplasticization requirements of sheet, uniform mixing, high-quality sheet andextruder series, suitable for various production requirements. The machineaccessories are all made of well-known brands at home and abroad to ensurethat the entire production process has high efficiency and stability. Applicationmaterials :PP, HIPS, PE,PET,PLA and other plastic sheet extrusion, for the production ofplastic packaging products thermoforming or printing products.

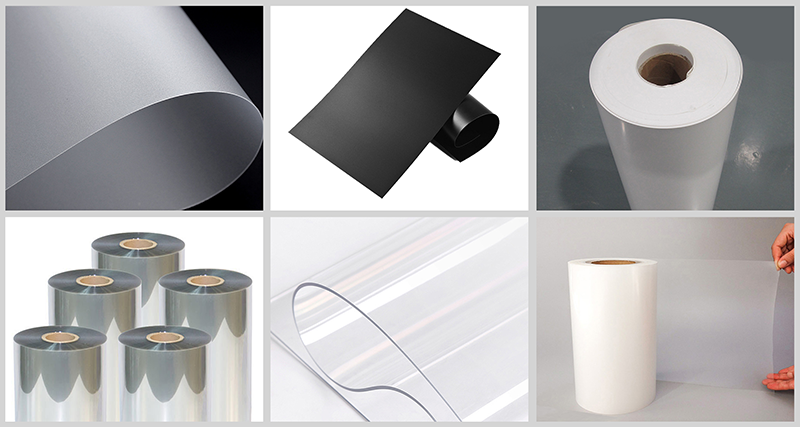

PP sheet PS sheet PE sheet and file

Double layer PP/PS/PE sheet

PET sheet,PLA sheet,BIO material sheet.

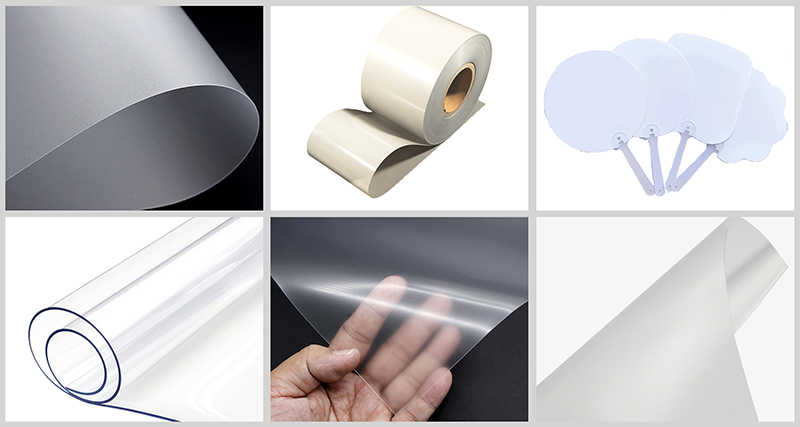

Paper Laminating

Paper LaminatingScope of application HLK series high-precision automatic card laminating machine, used for thin paper, cardboardgray board, coated paper and other processing requirements, to meet the double-sidedprinting and laminating, thin paper and thick paper and other special processingrequirements, high precision mounting, no deformation before and after laminating. Suitablefor wine box, shoe box, tag, card, toy, gift box and exquisite packaging products processingmounted paper with high flatness, high accuracy, good hardness and other characteristics.

Suitable for wine boxes,shoe boxes,tags,hanging cards,toys,gift boxes and exquisite packaging products processing.

Suitable for processing a variety of high flatness,

high precision outer packaging products color,carton.

lt can be connected with the paper mounting machine of anymanufacturer to stack the mounted paper according to the specified quantity.

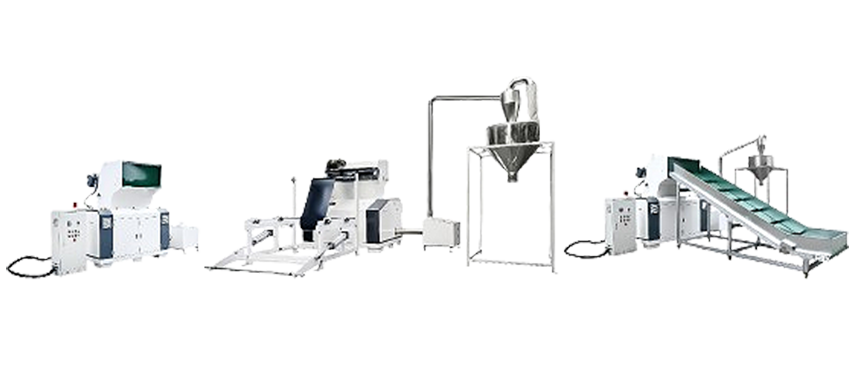

Auxiliary Equipment

Auxiliary EquipmentIn the mechanical production process, auxiliary equipment achieves efficiency enhancement through collaborative operation: the crusher crushes waste materials for raw material recycling; the feeder automatically transports materials, reducing manual labor and dust pollution; the air compressor provides pneumatic power to ensure precise equipment movement; the chiller cools components to maintain stable system operation; and the mold, custom-made with high precision, gives precise shape to the sheet. All equipment is interlocked, jointly constructing an efficient production system.

The temperature ofthe ironing head is too high or too low, and the position of the ironing head is too high or too low, which willcause the strapping to fail tobe ironed. (plastics of diferent qualities have diferent reasonable temperaures, and the entire temperature is in the range of 200-370°C)

The temperature ofthe ironing head is too high or too low, and the position of the ironing head is too high or too low, which willcause the strapping to fail tobe ironed. (plastics of diferent qualities have diferent reasonable temperaures, and the entire temperature is in the range of 200-370°C)

Normally we need around 45 days.

The temperature ofthe ironing head is too high or too low, and the position of the ironing head is too high or too low, which willcause the strapping to fail tobe ironed. (plastics of diferent qualities have diferent reasonable temperaures, and the entire temperature is in the range of 200-370°C)