×

×

Multi - station thermoforming is an advanced plastic - processing method. Heating plastic sheets, it shapes them in multiple stations simultaneously. This boosts efficiency and ensures high - precision results. It's widely used in packaging (for items like food containers), automotive (for interior parts), and consumer goods. As the plastics industry grows, multi - station thermoforming is vital for meeting demand for quality plastic products.

Mature Technology: Our factory leverages over a decade of industry experience and mature technology to support customization, ensuring tailored solutions for every client.

Invention Patents: We have successively obtained numerous invention patents, showcasing our commitment to innovation and quality.

High Precision and Automation: Our equipment boasts high precision, fast efficiency, and a high degree of automation, significantly enhancing productivity.

Labor Cost Reduction: Designed to reduce customer labor costs, our machines offer a cost-effective solution for your business.

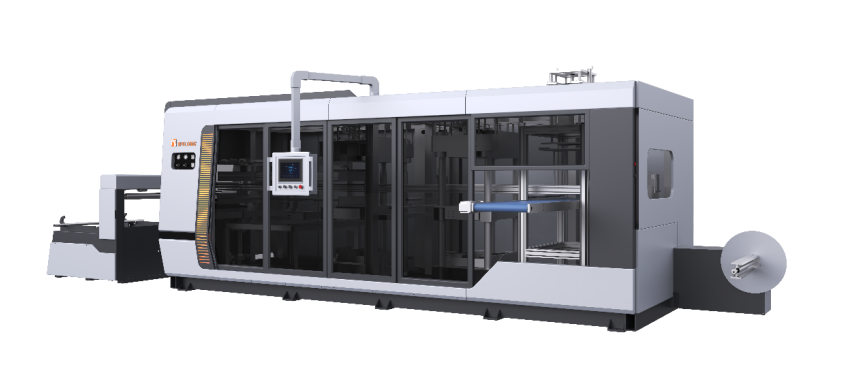

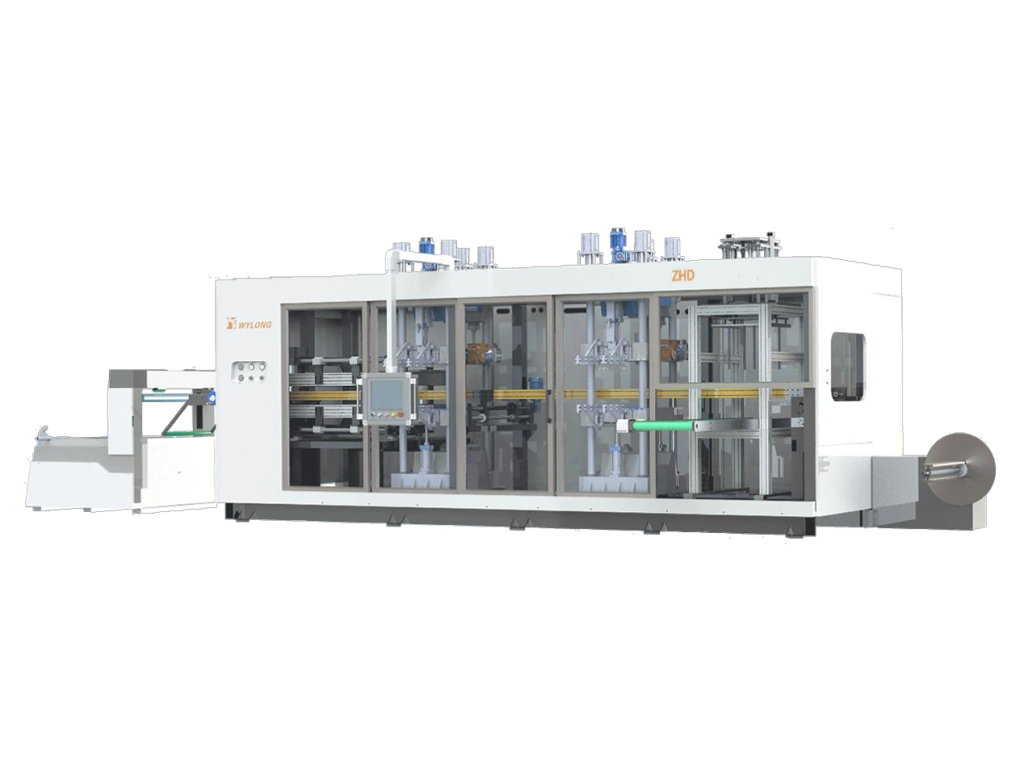

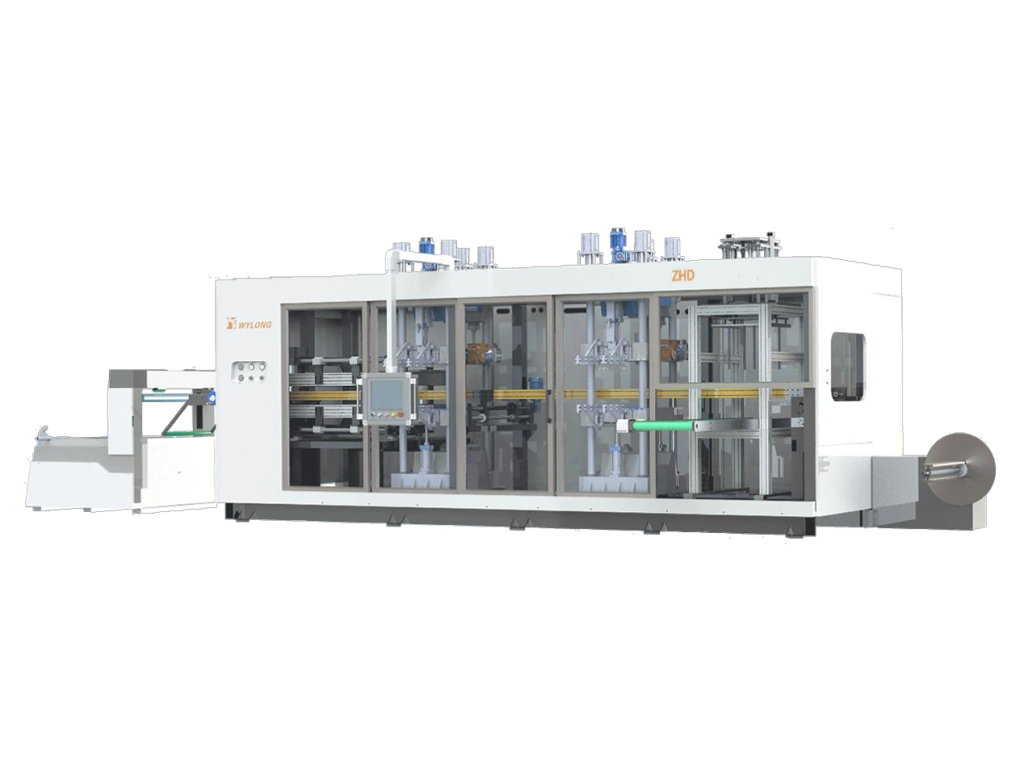

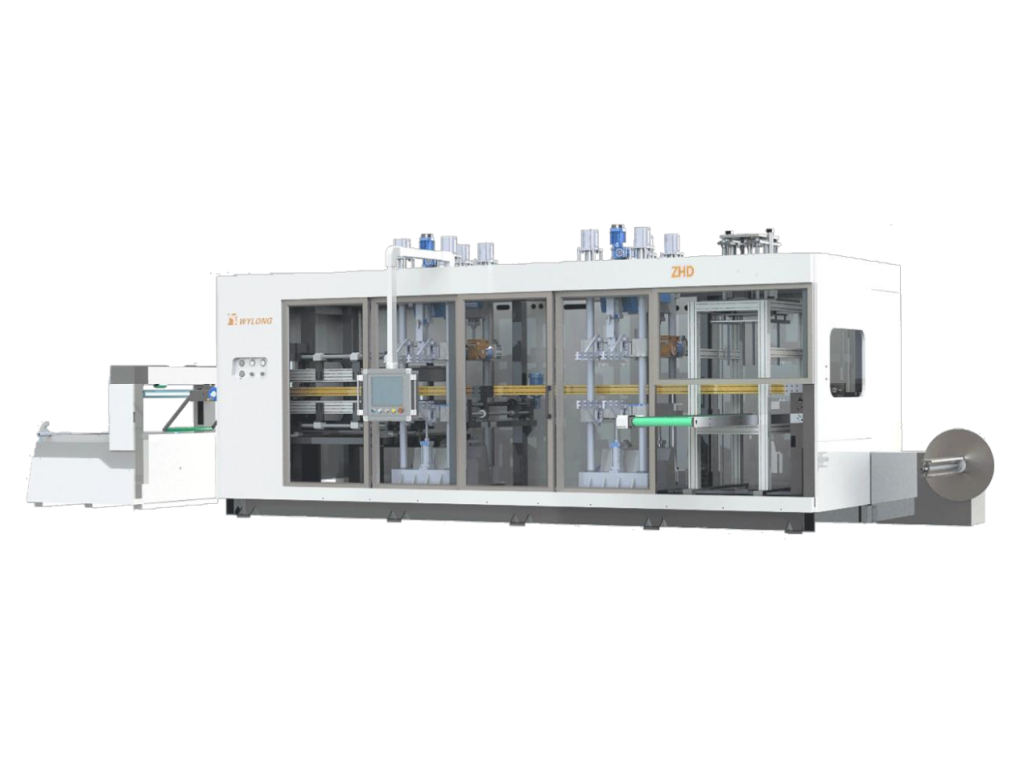

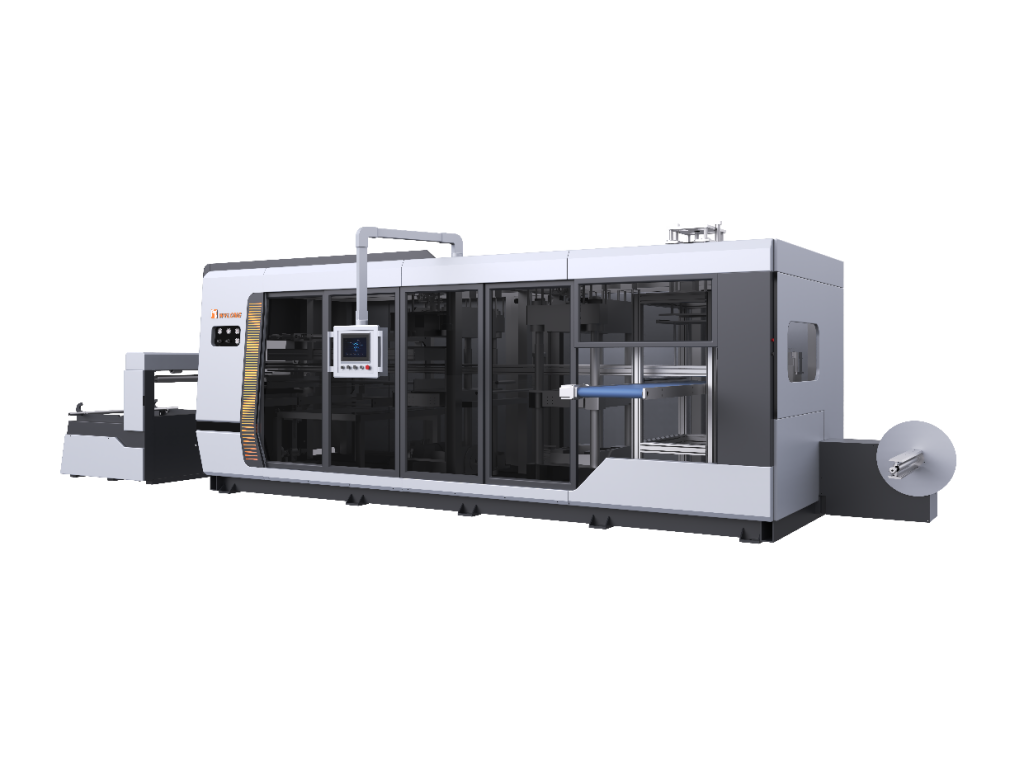

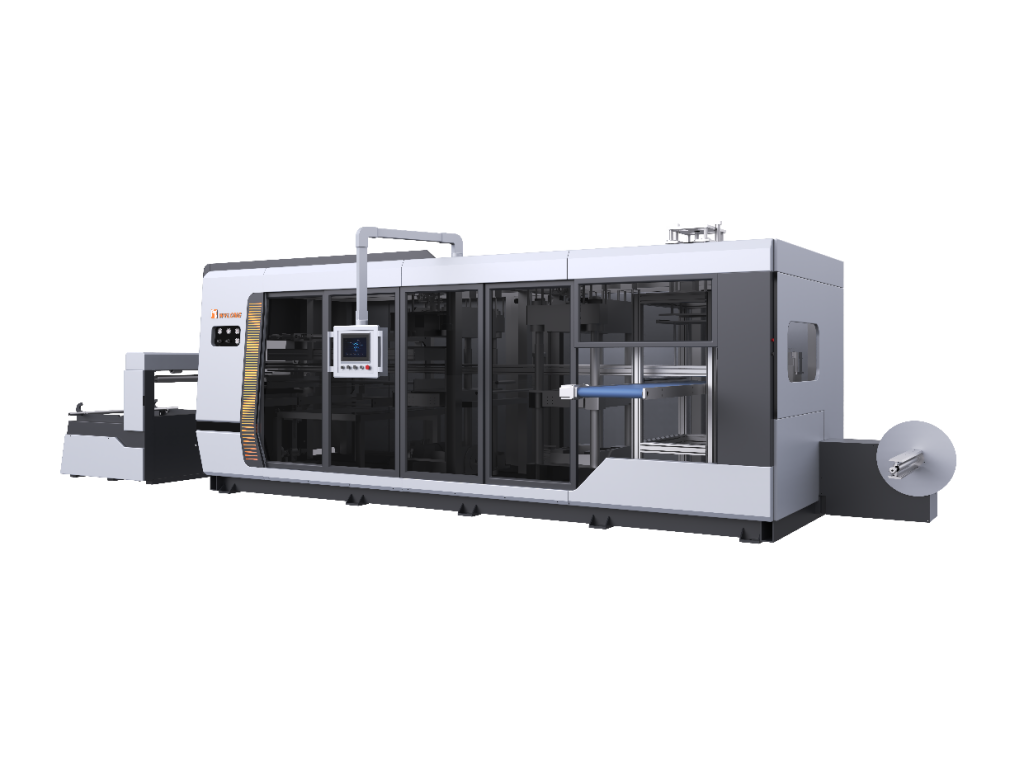

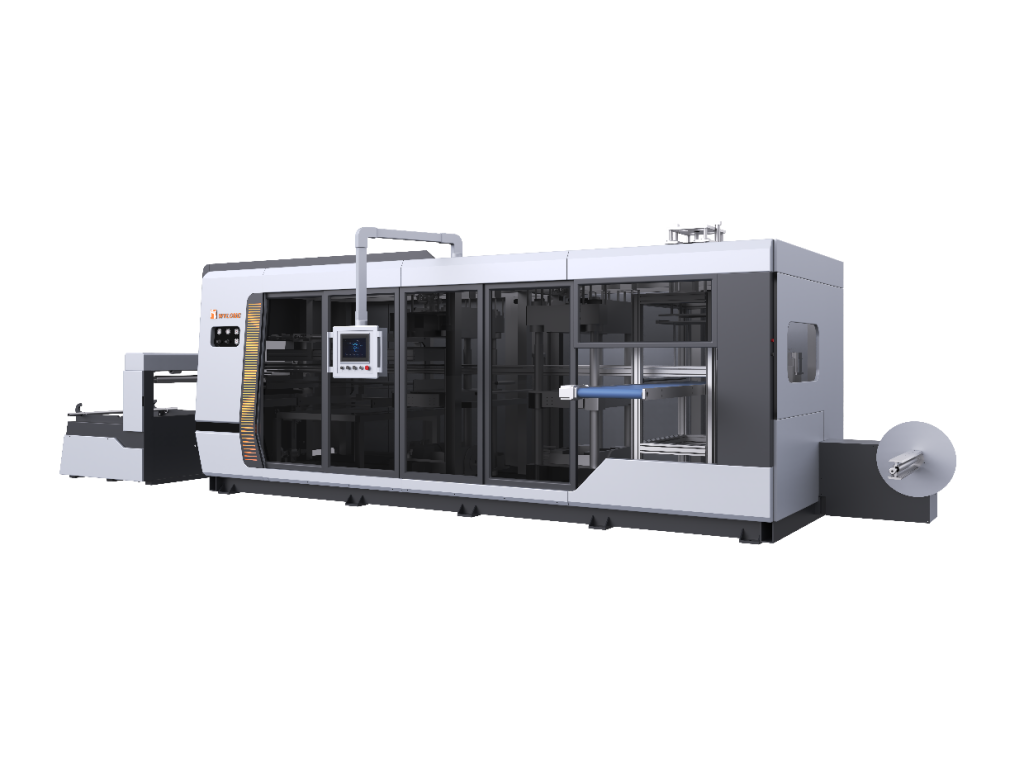

PRODUCTS

PRODUCTS· Sheet Materials:PP,PET,PVC,PS, PLA

· Sheet Thickness:0.2 – 1.5 mm

· Forming Area:600 * 400 mm

· Sheet Materials:PP,PET,PVC,PS, PLA

· Sheet Thickness:0.2 – 1.5 mm

· Forming Area:600 * 400 mm

· Sheet Materials:PP,PET,PVC,PS, PLA

· Sheet Thickness:0.2 – 1.5 mm

· Forming Area:680 * 500

· Sheet Materials:PP,PET,PVC,PS,PLA

· Sheet Thickness:0.2 – 2 mm

· Forming Area:750 * 650 mm

· Sheet Materials:PP,PET,PVC,PS,PLA

· Sheet Thickness:0.2 – 2 mm

· Forming Area:750 * 650 mm

· Sheet Materials:PP,PET,PVC,PS,PLA

· Sheet Thickness:0.2 – 2 mm

· Forming Area:780 * 850mm

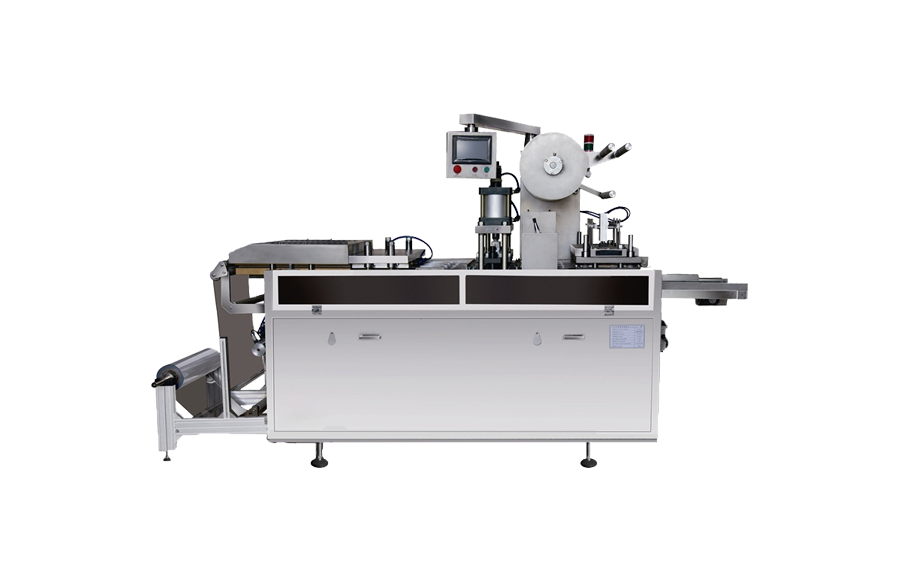

· Width of Sheet:450 – 800 mm

· Model:NU650/350丨NU750/450

· Sheet Materials:PP.PS.PET.PE.ABS

· Forming Pressure:0.5-0.8Mpa

· Model:NU650/350丨NU750/450

· Sheet Materials:PP.PS.PET.PE.ABS

· Forming Pressure:0.5-0.8Mpa

· Model:ZHBG-500

· Punch Speed:10-35 times/minute

· Max. Forming Size:470*290mm

· Model:ZHS800/450丨ZHS850-580

· Sheet Materials:PP.PS.PET.PE.ABS

· Sheet Thickness:0.3-2.0mm

· Model:ZHS800/450丨ZHS850-580

· Sheet Materials:PP.PS.PET.PE.ABS

· Sheet Thickness:0.3-2.0mm

Application

Application

Our factory is in Rui'an, Wenzhou, Zhejiang, China, you are welcome to visit us!

We are a factory with more than twenty years of experience in manufacturing machinery quality is worth guaranteeing

We accept T/T. 30% as deposit and 70% balance should be paid before delivery. We can also accept 100% confirmed irrevocable L/C at sight.

Yes, If the customer has no samples, please send a drawing or a photo of the sample, and let us know the size. Then we will send the drawing for your confirmation.

Normally we need around 45 days.