Choosing the right plastic sheet extruder is a critical procurement decision that directly affects product quality, production efficiency, operating cost, and long-term return on investment. For manufacturers in packaging, construction, medical, and industrial sectors, an unsuitable extruder can lead to thickness inconsistency, excessive scrap, high energy consumption, and frequent downtime.

This guide is written specifically for procurement managers, production engineers, and decision-makers who need practical, purchase-oriented insights. Instead of generic theory, it focuses on technology trends, capacity planning, material compatibility, and real-world applications—helping you confidently select a plastic sheet extrusion solution that aligns with your production goals today and scales for future demand.

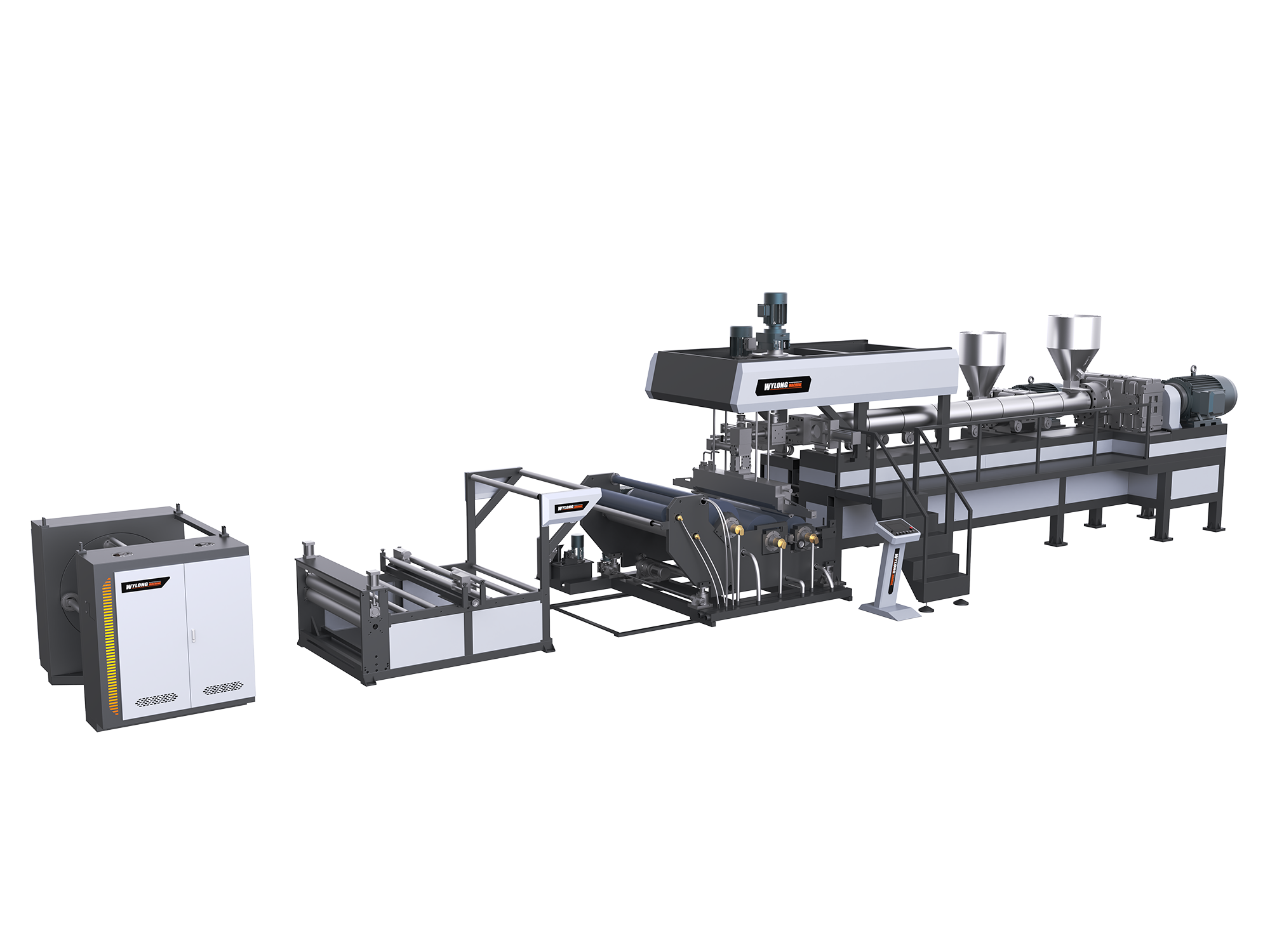

A plastic sheet extruder (also referred to as a plastic sheet extrusion machine) is industrial equipment designed to melt thermoplastic resins and form them into flat plastic sheets with controlled thickness and width. The extrusion process includes material feeding, plasticizing, extrusion through a flat die, cooling, and downstream handling.

From a procurement perspective, a plastic sheet extruder is not a standalone machine—it is the core of an entire extrusion line, determining:

A well-selected extruder ensures predictable production costs and stable product quality across large-volume runs.

Modern plastic sheet extruders increasingly adopt intelligent PLC and AI-assisted control systems. These systems continuously monitor temperature zones, melt pressure, screw speed, and line output.

For buyers, this translates into:

Intelligent control is no longer a premium option—it is becoming a baseline requirement for competitive sheet production.

Energy cost is a major factor in total ownership cost. New-generation extruders focus heavily on energy optimization, including:

For procurement teams, energy-efficient extruders offer measurable long-term savings, especially in high-output, continuous production environments.

Manufacturers are moving toward modular extrusion platforms that allow upgrades without replacing the entire machine. This flexibility is highly valuable for buyers facing uncertain future demand.

Key procurement advantages include:

Precision extrusion is essential for applications such as medical packaging, electronics trays, and high-end thermoforming. Advanced flat die technology and closed-loop thickness control systems enable:

Key Advantages of Modern Plastic Sheet Extruders

Key Advantages of Modern Plastic Sheet ExtrudersFrom a purchasing standpoint, leading plastic sheet extruders deliver value in five critical areas:

These advantages directly impact production reliability, customer satisfaction, and long-term profitability.

Food packaging applications demand strict hygiene standards and stable material performance. Extruders used in this sector must support food-grade materials and high-speed operation.

Typical requirements include:

For buyers, reliability and easy cleaning are key evaluation criteria.

PP hollow sheets are widely used in construction, signage, and protective panels. Extruders serving this market prioritize structural strength and production efficiency.

Procurement considerations include:

Medical packaging and device components require high-precision and contamination-controlled extrusion systems.

Key buyer requirements:

In this segment, machine precision and supplier credibility are often more important than initial equipment price.

Plastic sheet extruders are also used in:

Versatility and quick changeover capability are major advantages for manufacturers serving multiple markets.

When evaluating plastic sheet extruder suppliers, procurement teams should assess the following dimensions:

Evaluate automation, control accuracy, and energy efficiency. Higher technology levels typically deliver better long-term ROI.

Confirm the extruder’s hourly output matches your current and projected production needs. Undersized equipment creates bottlenecks, while oversized systems increase unnecessary investment.

Verify compatibility with all required resins, including recycled or specialty materials if applicable.

Request sample sheets and quality data to validate thickness tolerance, surface finish, and output stability.

Strong after-sales support, spare parts availability, and operator training are critical for minimizing downtime.

Many buyers encounter avoidable problems during extruder selection:

The solution is structured evaluation: technical discussions, sample testing, and clear performance benchmarks before final purchase.

How do I select the right extruder for different sheet thicknesses?

Focus on screw design, die precision, and cooling control. These factors directly affect thickness stability.

Can one plastic sheet extruder process multiple materials?

Yes, but buyers should confirm resin compatibility and cleaning requirements when switching materials.

What output capacity should I choose?

Capacity should be calculated based on sheet width, thickness, line speed, and annual production targets.

How important is supplier support?

Extremely important. Reliable support reduces downtime, protects production schedules, and lowers long-term risk.

Selecting a plastic sheet extruder is not simply an equipment purchase—it is a long-term production investment that influences efficiency, quality, and competitiveness. By focusing on technology level, capacity planning, material compatibility, and supplier support, procurement teams can significantly reduce operational risk and improve total cost performance.

For manufacturers seeking a reliable, scalable, and energy-efficient extrusion solution, partnering with an experienced supplier is essential. WYLONG provides plastic sheet extrusion systems designed for stable output, precise control, and long-term industrial use across packaging, construction, and medical applications.

If you are evaluating plastic sheet extruders for your next production upgrade or new project, working with WYLONG can help ensure your investment delivers consistent quality, production flexibility, and sustainable growth.