In 2025, manufacturers using Plastic Sheet Extruders face new pressures. Raw material costs have risen by 18% compared to last year. Buyers now expect faster turnaround times while still demanding high quality. Downtime and defective sheets are no longer acceptable. This guide presents five practical strategies to make Plastic Sheet Extruders run more smoothly, reduce costs, and increase output. Each method draws on 2025 industry data and insights from active manufacturers.

Efficiency goes beyond speed. It is about protecting profits. A 2025 survey from the Plastics Industry Association reported that inefficient Plastic Sheet Extruders cost manufacturers an average of $24,000 annually in wasted resin, rework, and downtime.

Two major trends highlight why efficiency matters more than ever:

Companies that fail to optimise their Plastic Sheet Extruders in 2025 risk losing ground to competitors who do.

Hygroscopic resins such as PET, PC, and nylon absorb moisture. Moisture leads to bubbles, colour defects, and rejected sheets. A 2025 study by Wylong Machinery found that poor drying increases scrap rates by 22%.

Steps to implement:

These steps can cut scrap rates and raise productivity. Mid-sized operations report monthly savings of about $3,600.

Single-screw extruders struggle with mixed resins. Twin-screw models improve mixing, reduce processing time by 15%, and ensure sheet consistency.

Why this matters in 2025:

Temperature swings cause uneven sheet thickness. Traditional thermostats cannot keep up with 2025’s faster production speeds. This leads to resin waste and rework.

The 2025 solution:

Manufacturers using Wylong’s smart Plastic Sheet Extruders report a 28% drop in rework and a 10% gain in output.

A worn screw reduces speed, causes uneven melting, and increases defects. Yet 40% of manufacturers still skip regular checks. Industry data shows that each unplanned shutdown costs about $2,000.

Checklist for 2025:

Following this routine can reduce unplanned downtime by 45%.

Material costs make up about 60% of extruder operating expenses. With virgin resin prices up by 22% in 2025, recycled blends are essential.

How to do it right:

Manufacturers using recycled blends have lowered production costs by 18% this year.

1.Extruder Jams

Cause: Contaminated resin or incorrect screw speed.

Fix: Add a magnetic separator and adjust screw speed based on resin type.

2.Slow Sheet Cooling

Cause: Weak airflow in the cooling tunnel.

Fix: Upgrade to a dual-fan cooling system. This reduces cooling time by 40% for thick sheets.

3.Inaccurate Thickness Gauging

Cause: Manual gauges with low precision.

Fix: Install a laser gauge for real-time measurement. This reduces thickness variation by 60%.

Improving efficiency in 2025 is not about buying entirely new equipment. It is about applying smart upgrades. Dry materials correctly. Use twin-screw extruders for blends. Add AI temperature controls. Maintain screws. Rely on recycled blends. Each step reduces costs and boosts output.

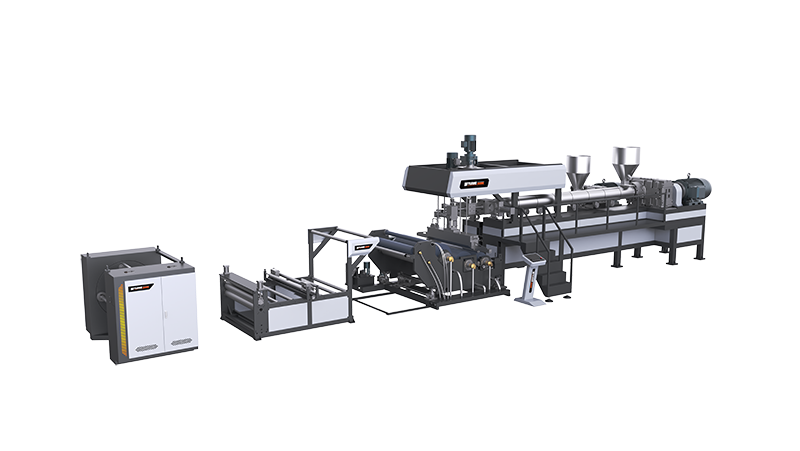

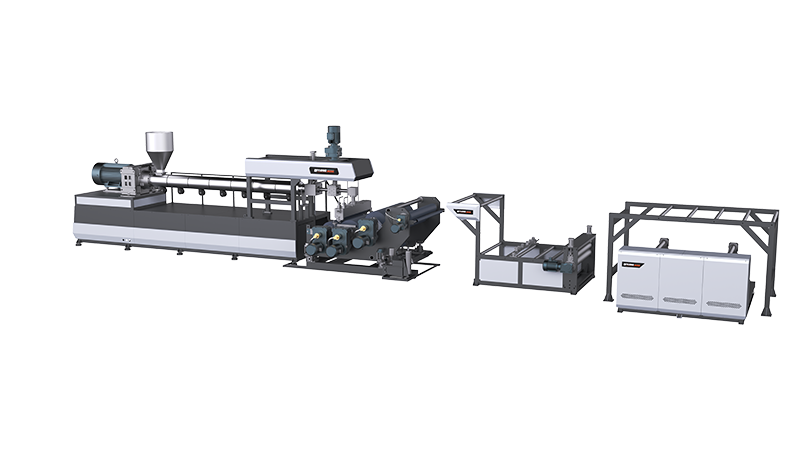

At Wylong Machinery, we design Plastic Sheet Extruders for maximum efficiency. Our systems include AI temperature controls, durable twin-screw models, and advanced drying solutions. We can audit your current setup and recommend tailored improvements. Contact Wylong Machinery today to book a free efficiency consultation.