|

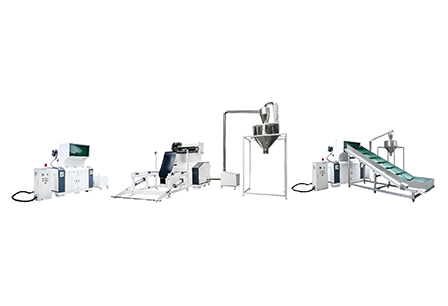

Vacuum Feeder |

Product overview:

1.Spiral circulation mixing makes the raw material mix more uniform and fast. |

Crystallization Dryer |

Product overview:

1.Screw feeding machine is specially cesigned and manufactured for plastic and powderproduction and processing industry, All the parts in contact with materials are made of stainlesssteel. lt can be used with all kinds of extruders, high-speed mixers and plastic mixers. Widelyused in all kinds of powder, granular, crushing and other materials on (feed) material use. |

Vacuum Feeder Vacuum Feeder |

Product overview:

Vacuum feeder series with high efficiency vacuum pump, power range from 4 to 7.5 kWtransmission capacity up to 1200 kg/h, the maximum transmission distance of 30 meters.The vacuum series is equipped with a tight drum filter, which combines the cyclone effectand dust separation perfectly, especially in the handling of dusty materials. |

Crystallization Dryer |

Product overview:

1.The product is suitable for the reuse of polymer recycled materials. In particular, PET recycled materials |

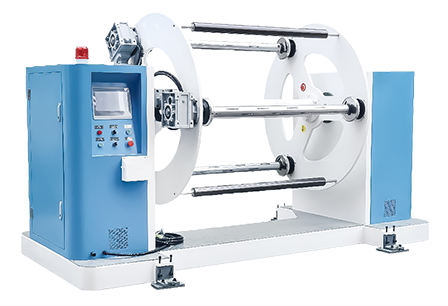

Winder Series Winder Series |

1.Applicable thickness: 0.1mm-1.2mm. 2.Applicable line speed: 1-100 meters per minute. 3.Applicable industry: sheet, sheet,(PET, PVC, PP, PS, PC, ABS, etc.) 4.Maximum winding weight: 1-1000KG. 5.Fixed disk design, safe and firm, beautiful appearance. 6.Motor control: complete servo motor control. 7. The model 3 inch air expansion shaft and 6 inch air expansion shaft, manual windincautomatic winding can be freely switched, optional automatic winding down air exhaustair expansion shaft on the air expansion shaft. |

Winder Series Winder Series |

1.Applicable thickness: 0.1mm-2.5mm 2.Applicable line speed: 1-100 meters per minute 3. Applicable industry: sheet, sheet (PET, PVC, PP, PS, PC, ABS, etc.) 4.Maximum winding weight: 1-1000kg 5.Fixed disk design, safe and firm, beautiful appearance 6.Multi-station design, double station, three stations, four stations 7.Motor control, can use torque, frequency conversion, servo. |

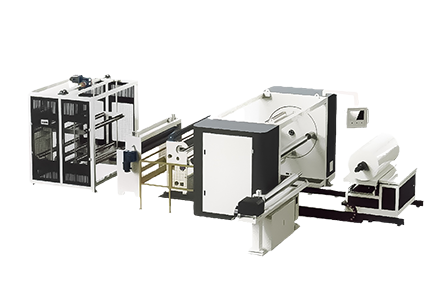

Multi-function And Powerful Silent Crusher Multi-function And Powerful Silent Crusher |

1.This product is suitable for the waste produced by various plasticproducts such as: PET, PP, PS, GAG, PC, PCV and other plastic productsedge material, roll material, plastic sucton. 2.Main structure: feeding frame, side material traction, crushing room, airfeeding system (screw feeding system’, material storage barrel. 3. The comprehensive seaing design, dust and noise reduclion ste is deaner and tidy. 4.Double inlet design, feeding can be rolled to achieve greater crushingability and save labor. 5.A, B double outlet, ton bag free switch without stop to replace the ton bagmore efficient. |

Sheet-wire Crusher Sheet-wire Crusher |

1.This product is mainly used for the crushing of the cuttingwaste produced by the sheet production line, such as PET,PPPS,GAG,PC, PCV and other plastic products. 2.Main structure: side material traction, crushing room, airsupply system, material storage barrel. 3.The comprehensive sealing design, dust and noise reductionsite is cleaner and tidy. 4. Double station or single station general design, can beselected according to the actual situation to save more sitespace. |

Previous:

Next article: PFP printing south China 2024