Thermoforming is a cornerstone process in plastic packaging and manufacturing, involving heating plastic sheet to mold it into customized shapes for industries like food packaging, medical supplies, and consumer goods. The performance of your thermoforming machine directly impacts production efficiency, product quality, and ultimately, your return on investment (ROI). Two primary types dominate the market: servo-driven thermoforming machines and pneumatic thermoforming equipment. Whether you’re scaling production, launching a new line, or upgrading existing gear, understanding their core differences is critical to saving costs, avoiding operational headaches, and maximizing long-term profitability. This guide breaks down their key attributes, production impacts, and ROI potential to help you make an informed choice.

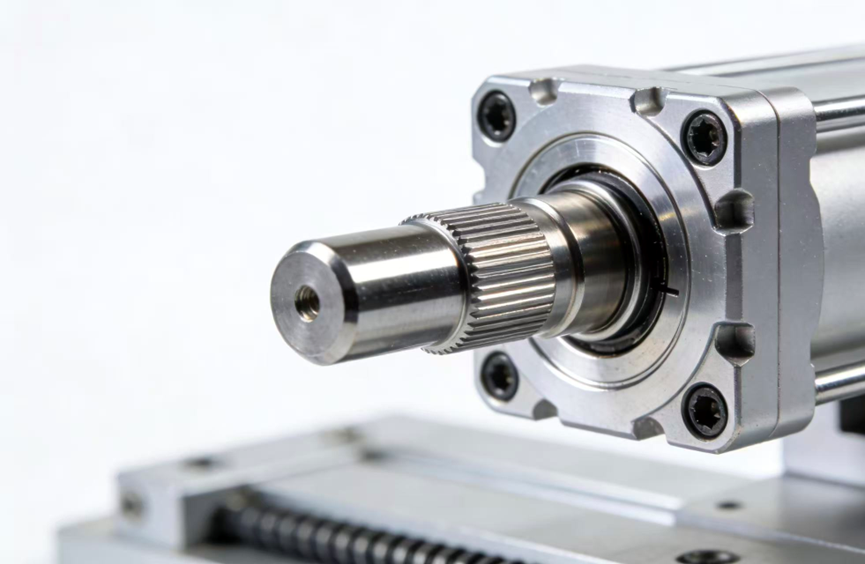

The fundamental distinction between the two machines lies in their drive systems, which dictate control, precision, and efficiency:

To evaluate which aligns with your needs, compare their key features in this structured table:

| Aspect | Servo Thermoforming Machine | Pneumatic Thermoforming Equipment |

| Energy Efficiency | Energy Efficiency Exceptionally high, servo motors only draw power when in motion, cutting down on wasted energy. This aligns perfectly with the demand for energy efficient thermoforming solutions that lower utility bills. | Relatively low, pneumatic systems require a constant supply of compressed air, which often leaks or operates at less than optimal efficiency, driving up energy costs over time. |

| Precision | Unmatched. These machines can replicate movements to fractions of a millimeter, ensuring every part meets exact quality standards. | Moderate at best. Air pressure fluctuations can throw off alignment, leading to slight variations in finished products. |

| Speed | A standout for high-speed thermoforming. Servo motors accelerate and decelerate rapidly, shrinking cycle times and boosting overall output, critical for meeting large orders. | Steady but slower. Pneumatic systems can’t match the quick, controlled movements of servo motors, making them better suited for low-volume runs. |

| Maintenance | Minimal. With fewer moving parts prone to wear, thermoforming machine maintenance becomes a breeze, less downtime, fewer replacement parts, and lower long-term costs. | More intensive. Compressors, hoses, and valves all require regular checks and replacements, adding to operational overhead and potential production gaps. |

| Cost | Higher upfront investment. The advanced technology behind servo systems comes with a higher price tag, though this is often offset by long-term savings. | Budget-friendly to start. Pneumatic machines have a lower initial cost, making them accessible for businesses with limited capital. |

5.ROI Analysis: When to Choose Which?

ROI depends on upfront costs, operational expenses, and production needs. Here are two key scenarios:

Scenario A: High Volume, High Quality

If your business produces thousands of units daily with strict quality requirements (e.g., medical trays, premium packaging), a servo-driven thermoforming machine is a wise long-term investment. Energy savings alone (30–50% compared to pneumatic models) can recoup the higher upfront cost within 1–2 years. Its speed, precision, and low maintenance also reduce downtime and material waste, maximizing profitability for scaling operations.

Scenario B: Low Budget, Simple Parts

For small businesses, startups, or those producing basic components (e.g., simple plastic containers) with lenient quality standards, pneumatic thermoforming equipment is an economical starting point. Its lower upfront cost is accessible for limited capital, and performance is sufficient for uncomplicated tasks. However, factor in higher energy and maintenance costs over time.

Do servo thermoforming machines use any air?

Yes. However, compared with pneumatic systems, this situation is much less common. Most servo equipment only uses compressed air for specific tasks rather than throughout the entire operation. This limited use means less wasted energy in air compression and no need to worry about more leakage problems.

How much electricity does a servo machine save?

This varies by application, but many users report cost savings of 30% to 50% compared to pneumatic machines. WYLONG‘s servo models have been optimized for energy efficiency. With their advanced motor technology, they typically achieve the higher end of this range.

What are the differences between a servo hot forming machine and an pneumatic hot forming machine?

The main difference lies in the drive system. The servo machine uses electric servo motors for precise and programmable motion control. In contrast, the pneumatic machine relies on pneumatic cylinders. This enables the servo machine to achieve higher precision and faster cycle times.

Is the servo hot forming machine more expensive than the pneumatic hot forming machine?

The initial purchase price of the servo machine is usually higher than that of the equivalent pneumatic model. However, it can save more on energy costs. At the same time, its maintenance requirements are low and the production efficiency is higher. Therefore, the servo machine can usually achieve a quick ROI.

The choice between servo-driven and pneumatic thermoforming machines hinges on your production volume, quality requirements, and budget. The models excel in high-volume, precision-focused workflows—delivering energy efficiency, consistent quality, and low maintenance that drive long-term ROI. Pneumatic equipment is a cost-effective solution for small-scale operations or simple products, though it comes with higher ongoing energy and maintenance costs.

To maximize ROI, align your choice with your long-term goals: Scale-focused businesses or those needing strict quality control will benefit from servo-driven machines, while budget-constrained startups or low-volume producers can start with pneumatic equipment. Brands like WYLONG offer both options—optimized servo models for efficiency and durable pneumatic systems for cost-effectiveness—paired with reliable components to minimize downtime.

Ready to select the right thermoforming machine for your ROI goals? Contact WYLONG today for a free quote, technical consultation, and tailored recommendations based on your production volume, product specifications, and budget.