In the global shift toward sustainable plastic manufacturing, biodegradable material has become a cornerstone of eco-friendly production—yet processing these unique polymers poses distinct challenges that standard plastic extrusion equipment cannot address. Biodegradable extruders are engineered to overcome bioplastics’ inherent limitations, from poor blend adhesion to thermal degradation, while elevating the quality across every stage. For manufacturers invested in plastic sheet extrusion and film applications, these specialized machines are not just an upgrade; they’re the critical link between sustainable goals and consistent, high-performance end products. This guide breaks down how they transform material compatibility and quality, and why they’re non-negotiable for forward-thinking production.

Standard plastic sheet extrusion machine systems are designed for stable thermoplastics like PE and PP, but the material (e.g., PLA, PHA, starch blends) is heat-sensitive, prone to degradation, and often requires blending with bio-fillers—making it incompatible with one-size-fits-all equipment.

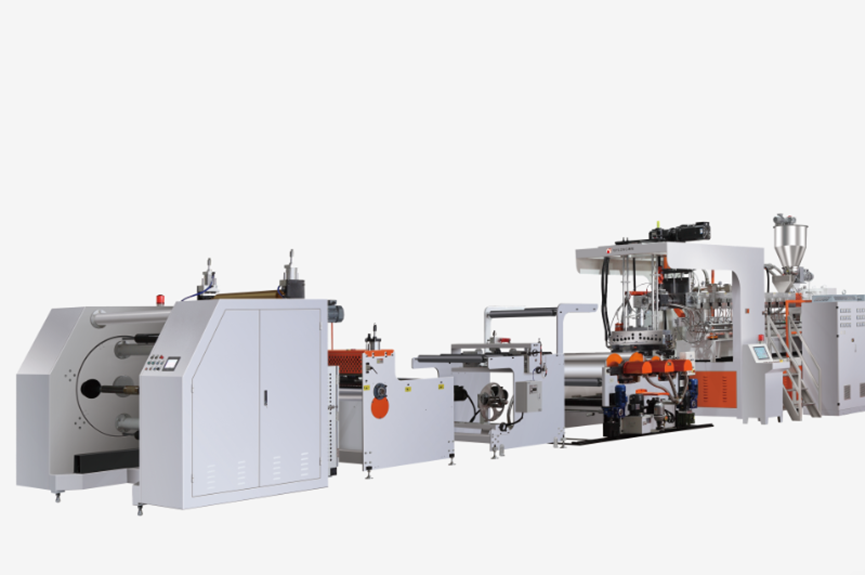

A purpose-built biodegradable extruder features targeted modifications: gentle shear screws to avoid thermal breakdown, precision temperature control (10–20°C lower than traditional plastics), and specialized feed systems for bulkier bio-based materials. For sheet extrusion line operations, these tweaks eliminate scorching, inconsistent melt flow, and poor blend uniformity—laying the groundwork for better material compatibility and extrusion quality.

Material compatibility is the biggest hurdle in biodegradable processing; bioplastics often fail to bond with other polymers, fillers, or additives, leading to weak end products. Biodegradable extruders address three key pain points for the sheet extrusion and film applications.

Many biodegradable formulations blend biopolymers (e.g., PLA + PHA) or bioplastics with bio-fillers, which suffer from poor interfacial adhesion—resulting in brittle, layered extrudate. Biodegradable extruders use twin-screw designs with low-shear mixing zones that fuse components at the molecular level, creating a homogeneous melt. For plastic sheet extrusion, this means a cohesive material with consistent properties across the entire product—something standard extruders can’t achieve.

The material is highly sensitive to heat and shear; even small deviations in the process break down its molecular structure. Standard plastic extrusion equipment generates high shear and hot spots, but biodegradable extruders feature optimized screw geometry (shallow flights, low compression ratios) and multi-zone temperature control to maintain stable, low melting temperatures. This preserves the material’s integrity, ensuring the final sheet retains its intended mechanical and biodegradable properties.

Functional additives (UV stabilizers, plasticizers) or bio-fillers (hemp fiber, rice husk) often have poor compatibility with biopolymer melts, leading to agglomeration or reduced strength. Biodegradable extruders include dedicated additive feeding ports and inline mixing modules that meter ingredients at the optimal stage, ensuring uniform dispersion without degradation. For the sheet extrusion, this means additives enhance performance (e.g., UV resistance for agricultural sheets) without compromising quality.

Solving material compatibility challenges directly translates to measurable the quality gains—biodegradable extruders produce end products that match traditional plastics’ performance while retaining eco-friendly properties.

Bioplastics processed on standard extruders often lack tensile strength and impact resistance due to poor blending and degradation. Biodegradable extruders create homogeneous melts with intact molecular structures, resulting in sheets and films with 30–50% higher strength—performing as well as traditional plastics for packaging, mulch, and industrial use.

Standard extruders produce biodegradable products with inconsistent thickness (±10% variation) and weak barrier properties. Biodegradable extruders deliver precise melt control, resulting in ±3% thickness uniformity, smooth surfaces, and 25–40% lower oxygen/moisture transmission rates—critical for food packaging that extends shelf life.

Poor compatibility leads to 15–20% scrap rates with standard plastic sheet extrusion machine systems. The extruders offer exceptional process stability, cutting scrap to 5–8% through consistent melt flow and temperature control. This reduces raw material waste and boosts production efficiency for manufacturers.

Biodegradable film production relies on two primary extruder configurations, tailored to different needs:

| Extruder Configuration | Core Design | Key Advantages | Ideal Applications |

| Twin-Screw Co-Rotating | Low-shear intermeshing screws, multi-zone temp control | Superior blending, minimal degradation | High-performance films (food/medical packaging) |

| Single-Screw Optimized | Shallow-flight screw, precision die head | Cost-effective, energy-efficient | Cost-effective, energy-efficient |

Both integrate seamlessly with downstream film equipment, ensuring a smooth extrusion process for biodegradable materials.

Biodegradable extruders deliver tailored value across key applications:

While biodegradable extruders cost 20–30% more upfront than standard equipment, their long-term benefits drive ROI within 24–36 months:

Q1: Can standard plastic sheet extrusion machines be modified for biodegradables?

Minor tweaks (e.g., temp control upgrades) may work for basic bioplastics but fail to solve material compatibility or degradation issues. A purpose-built biodegradable extruder is required for consistent the quality.

Q2: What materials can biodegradable extruders process?

They handle all common bioplastics (PLA, PHA, PBAT, starch blends) plus bio-fillers and functional additives, supporting versatile production.

Q3: Is specialized training needed for operation?

Basic operation mirrors standard plastic sheet extrusion line systems, but training is recommended for optimizing bioplastic processing. Most manufacturers include this with equipment purchases.

Q4: What features should I prioritize when choosing one?

Look for low-shear screws, precision temperature control, additive feeding ports, and process stability—WYLONG’s biodegradable extruders include these as standard, plus modular designs that scale from film to plastic sheet extrusion.

Investing in a biodegradable extruder is a value-driven decision that unlocks the material’s full potential by solving the compatibility challenges and matching traditional plastics’ extrusion quality. The core value of these machines lies in their ability to turn bioplastics—once low-performance and problematic—into high-quality, consistent products that meet application demands while staying eco-friendly. Unlike standard plastic extrusion equipment, they eliminate the trade-off between sustainability and performance, creating a path to profitable, compliant production.

This value extends beyond the factory floor: biodegradable extruders open premium markets, ensure regulatory compliance, and build brand credibility around sustainability. In a world where eco-friendliness is mandatory, they’re a strategic asset for long-term success.

WYLONG stands out for engineering biodegradable extruders that balance specialized processing with practicality—every model is built for optimal compatibility and quality, with modular designs scaling from film to plastic sheet extrusion line systems. The brand’s focus on equipment value ensures long-term reliability, minimal maintenance, and maximum efficiency for sustainable manufacturing.

Ready to unlock biodegradable material’s potential for your plastic sheet extrusion or film production? Unsure which the extruder fits your needs? Reach out to WYLONG’s sustainable extrusion experts today for a personalized assessment, custom solution recommendation, and end-to-end support. Get your consultation and quote now to step into high-quality, profitable sustainable plastic production!