Thermoforming is one of the most widely used manufacturing processes for producing lightweight, durable, and cost-effective plastic components. From medical trays to automotive panels and retail packaging, thermoforming plays a crucial role in modern production. Choosing the right thermoforming plastics—and pairing them with the right thermoforming machine—is essential for achieving optimal performance, product quality, and production efficiency.

This complete guide explains what thermoforming plastics are, their key performance indicators, commonly used material types, selection strategies, and how to ensure the best results for your application.

Thermoforming plastics are polymer sheets that become moldable when heated and form into specific shapes using vacuum forming, pressure forming, or mechanical forming. Once cooled, these plastics retain their new shape with excellent strength and dimensional stability.

Thermoforming plastics are widely used with:

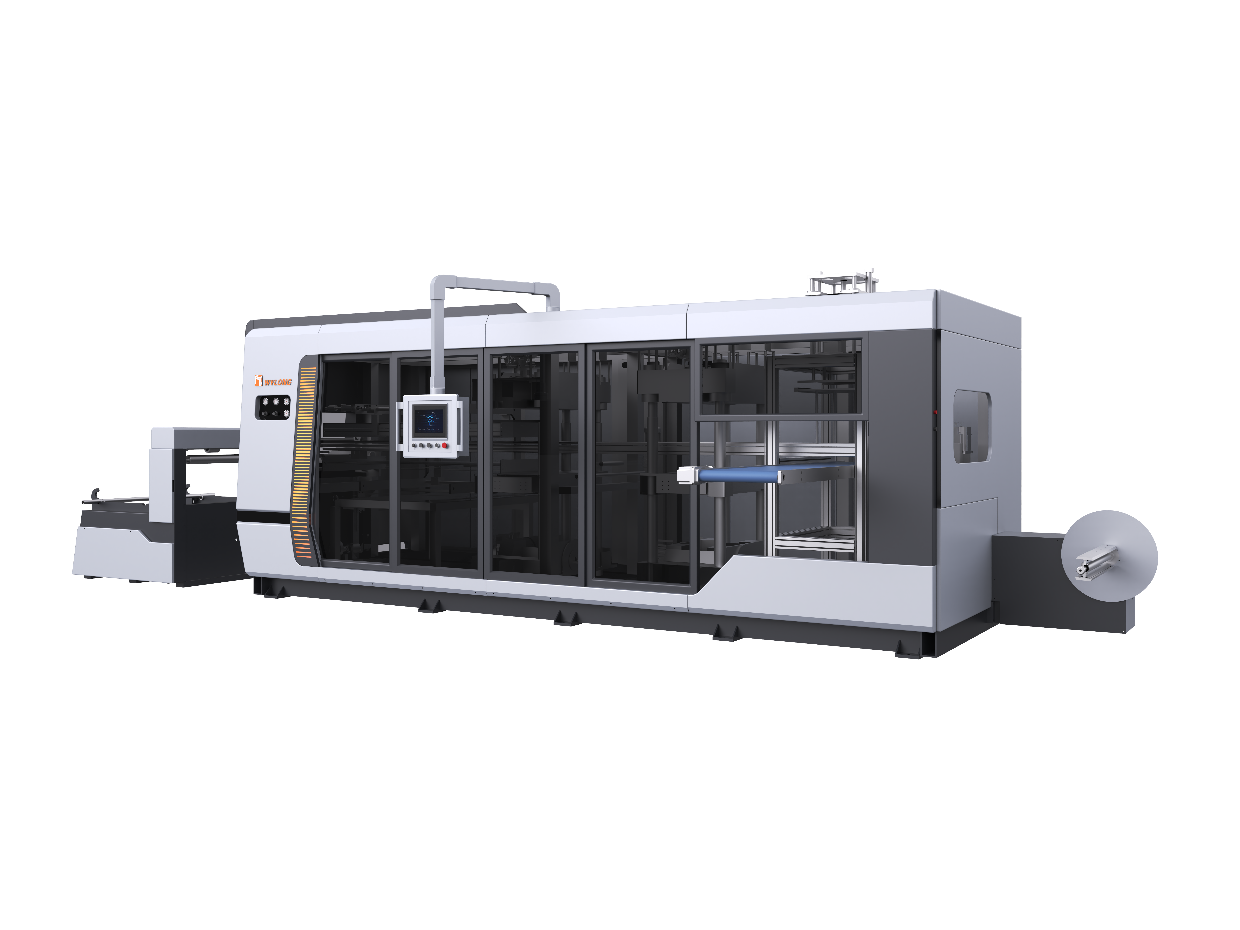

Plastic thermoforming machines

Thermoforming packaging machines

Industrial thermoforming equipment

These materials are ideal for creating consistent, high-volume thermoformed plastic products, including housings, enclosures, packaging, panels, containers, and protective components.

To achieve the ideal balance of strength, appearance, durability, and processing efficiency, manufacturers evaluate several critical property indicators.

Indicates how well a material maintains structural integrity under heat. Plastics with higher HDT are better suited for high-temperature environments or industrial applications.

Reflects the material’s ability to withstand stretching forces. High tensile strength ensures dimensional stability and prevents tearing during forming.

Measures resistance to sudden force or mechanical shock. Crucial for automotive panels, protective covers, and heavy-duty packaging.

Determines how much a plastic contracts after cooling. Low shrinkage improves dimensional accuracy and reduces mold modification requirements.

Protects against degradation caused by oils, solvents, acids, cleaners, and environmental contaminants. Important for industrial and medical applications.

Below are the most frequently used plastics in thermoforming, each offering unique advantages.

Excellent impact strength

Good surface finish

Moderate cost

Ideal for automotive interiors, machine housings

Easy to thermoform

Cost-efficient

Suitable for disposable trays, packaging inserts

High clarity and toughness

Great for medical trays and retail packaging

FDA-compliant options available

Chemical resistant

Good formability

Popular in construction and clamshell packaging

Extremely strong and heat resistant

Excellent optical clarity

Used for protective shields, equipment covers, outdoor products

High moisture resistance

Lightweight and flexible

Ideal for food containers, automotive battery covers

Highly impact resistant

Weather-resistant

Used for outdoor components, fuel tanks, industrial trays

Exceptional clarity

Strong UV resistance

Common in signage, displays, lighting components

Each material behaves differently when processed with a thermoforming machine, so matching plastic performance with production needs is essential.

Choosing the right material involves evaluating performance requirements, forming behavior, and end-use conditions.

Consider temperature exposure, load-bearing needs, impact resistance, and environmental challenges.

Match HDT, tensile strength, impact strength, and shrinkage rates to your design goals.

Different plastics respond uniquely to heat—some form easily while others require precise control from the thermoforming equipment.

For medical, food, or electronics packaging, choose materials that meet FDA, ISO, or ROHS standards.

Balance high-performance materials (PC, PETG) with cost-effective options (HIPS, PP).

Follow these steps to select the ideal material for your application:

Step 1: Assess End-Use Environment

Outdoor? High-heat? High-impact? Clean room use?

This determines whether you need PC, PP, HDPE, or specialty plastics.

Step 2: Match with Production Capabilities

Ensure your plastic thermoforming machine can handle the selected plastic’s heating and cooling characteristics.

Step 3: Evaluate Aesthetics & Surface Finish

For consumer products, surface appearance and color stability are essential.

Step 4: Prototype & Test

Perform forming trials and durability testing before committing to full-scale production.

Step 5: Consult Thermoforming Suppliers

Experienced thermoforming suppliers can provide technical guidance and material samples for evaluation.

Can all plastics be thermoformed?

No. Only thermoplastic polymers that soften when heated—such as ABS, HIPS, PC, PETG, PP, PMMA, and HDPE—are suitable for thermoforming.

Which thermoforming plastic is best for high-temperature applications?

Polycarbonate (PC) and certain high-performance blends offer excellent heat resistance and withstand elevated operating temperatures.

How to test material suitability before mass production?

Manufacturers conduct heat cycle testing, impact testing, forming trials, and prototype evaluations using actual thermoforming equipment.

Thermoforming plastics provide unmatched versatility for manufacturing cost-effective, high-quality components across nearly every industry. By understanding material properties—such as heat resistance, impact strength, and chemical durability—you can select the ideal polymer for your product design. Pairing the right material with an advanced thermoforming machine, thermoforming packaging machine, or large-format thermoforming equipment ensures consistent performance and production efficiency.