If you’re looking to get the most out of your twin screw extruder or enhance your plastic extrusion line efficiency, this guide is your go-to resource. We’ll break down what a twin screw extruder is, explore key optimization strategies, and demonstrate how to tailor solutions for different industries. Plus, we cover common problems, screw configuration tips for twin screw extruder, and provide answers to procurement-focused questions, helping you make smarter equipment decisions.

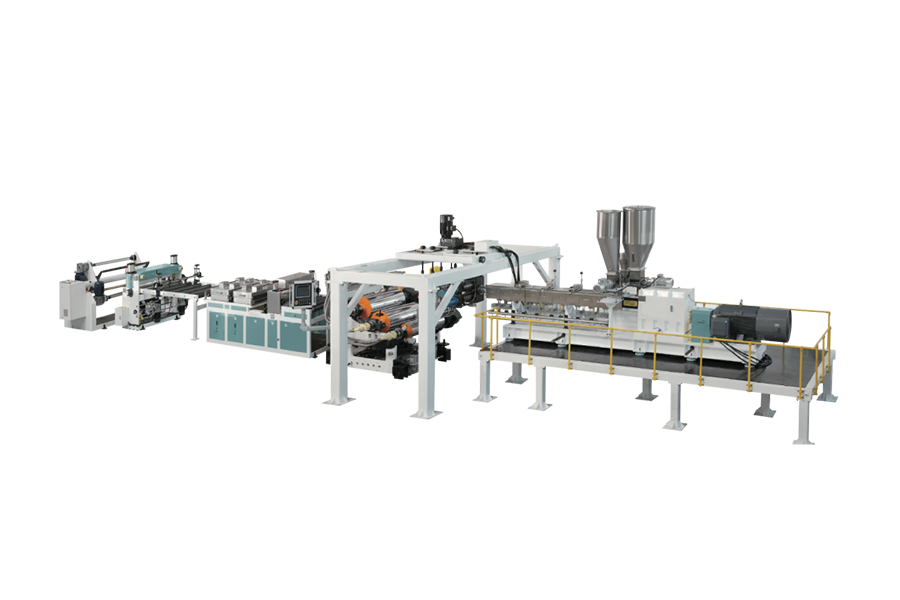

A twin screw extruder is a versatile machine used to mix, compound, and process polymers and other materials. Unlike single screw extruders, it features two intermeshing screws that rotate inside a barrel, providing superior mixing and conveying capabilities.

Benefits for procurement and production:

Understanding the twin screw extruder’s capabilities helps buyers make informed decisions when evaluating plastic sheet extruder solutions.

Optimizing the screw configuration for twin screw extruder ensures efficient melting, mixing, and conveying.

Temperature and screw speed work together to affect product quality and throughput.

Proper pressure and vacuum settings are critical for degassing and consistent output.

| Industry | Application Example | Customization Focus | Benefits | Challenges Addressed |

|---|---|---|---|---|

| Plastics | Polymer compounding | Screw design, temperature zones | Improved mixing, reduced defects | Handling diverse polymers |

| Food | Starch modification | Gentle mixing, precise heating | Preserves nutrients and texture | Heat-sensitive materials |

| Pharmaceuticals | Granulation and drying | Vacuum control, screw speed | Consistent particle size | Moisture removal and product stability |

| Chemicals | Reactive extrusion | Pressure control, screw profile | Enhanced reaction efficiency | Handling volatile byproducts |

| Problem | Cause | Solution | Monitoring Method | Impact |

|---|---|---|---|---|

| Material degradation | Excessive heat or shear | Optimize temperature zones and reduce screw speed | Temperature sensors | Reduced product quality |

| Inconsistent mixing | Improper screw configuration | Customize screw elements to material needs | Visual inspection | Material waste, low uniformity |

| Pressure fluctuations | Blockages or feed issues | Monitor pressure and maintain feed systems | Pressure sensors | Inconsistent output |

| Vacuum leaks | Seal issues | Inspect seals and vacuum lines | Vacuum gauge | Poor degassing |

| Screw wear | Long-term use | Routine inspection and replacement | Torque measurement | Reduced efficiency and product quality |

Optimizing screw setups is critical for material-specific extrusion.

This ensures consistent product quality and operational efficiency across different production lines.

What critical parameters should I monitor for twin screw extruder?

Barrel temperature, screw speed, melt pressure, vacuum level, and torque ensure stable operation.

Can twin screw extruders handle multiple materials simultaneously?

Yes, they excel at processing blends and composites for uniform mixing.

How to maintain product consistency during long runs on twin screw extruder?

Keep process parameters stable, perform regular maintenance, and use real-time monitoring.

Is screw wear a major concern for twin screw extruder?

Yes, worn screws reduce mixing efficiency and output quality. Regular inspection and replacement are crucial.

Are twin screw extruders energy efficient?

Modern designs with optimized screw profiles and variable speed drives reduce energy consumption while maintaining output quality.

Which twin screw extruder is best for specific industry applications?

Consult the customization table above and consider supplier expertise for food, pharma, plastics, or chemical processing.

Optimizing your twin screw extruder involves balancing components, process parameters, and material compatibility. By tailoring screw configurations, controlling temperature and pressure precisely, and adapting solutions to your industry needs, you ensure stable, efficient production.

For procurement professionals, understanding these factors empowers smarter investments. Partnering with a trusted supplier like WYLONG provides tailored twin screw extruder solutions, technical support, and energy-efficient designs, ensuring your extrusion process achieves maximum performance and long-term reliability.