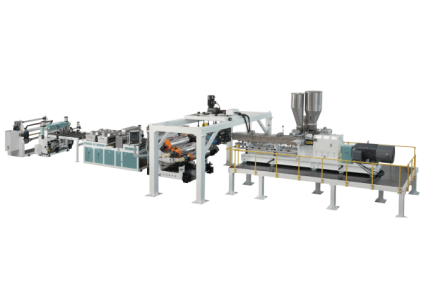

Multi-layer co-extruded films are one of the most important downstream products produced by a plastic sheet extruder. For manufacturers operating plastic sheet extrusion lines, the selection of film structure directly affects product performance, production efficiency, and overall return on investment.

From a procurement perspective, choosing the right plastic sheet extruder and co-extruded film solution is no longer just about output capacity. It impacts material utilization, energy consumption, compliance requirements, and long-term supply stability. This guide is written specifically for buyers evaluating plastic sheet extruder applications, explaining how multi-layer co-extrusion technology works, where it is used, and how to align extruder capability with real industrial demand.

Multi-layer co-extrusion film technology is a core process enabled by a plastic sheet extrusion machine. It produces high-performance co-extruded plastic sheets and films by combining multiple polymer layers into a single structure during extrusion.

In a typical plastic sheet extruder line, different polymers are plasticized, distributed, and merged through a multi-manifold or feedblock die. Each layer serves a specific function—barrier protection, mechanical strength, sealability, or surface performance.

Key characteristics include:

For procurement teams, this technology allows better alignment between plastic sheet extruder investment and final product requirements.

From a procurement standpoint, the value of multi-layer co-extruded films lies in their ability to deliver measurable business benefits, not just technical performance.

| Advantage | Technical Explanation | Procurement Value | Business Impact |

|---|---|---|---|

| Superior Barrier Performance | EVOH or nylon layers block oxygen and moisture | Longer shelf life, fewer returns | Reduced spoilage and compliance risk |

| Enhanced Mechanical Strength | Structural layers improve puncture and tear resistance | Safer transport and handling | Lower damage claims and repackaging cost |

| Reliable Sealability | Dedicated sealant layers ensure consistent sealing | Stable packaging line performance | Higher line efficiency, fewer stoppages |

| Optimized Cost Structure | Barrier resins used only where needed | Lower cost per unit | Improved margin control |

| Lightweight Design | Thinner films achieve equal performance | Reduced material usage | Lower logistics and carbon footprint |

Food packaging is one of the largest application areas for co-extruded films. These films are widely used in snack packaging, fresh produce, frozen foods, and ready-to-eat products.

Procurement-driven requirements include:

By selecting the correct layer structure, buyers can significantly reduce food waste and improve shelf stability.

Pharmaceutical packaging requires strict control over barrier performance and material consistency.

Key evaluation factors for buyers:

In this segment, consistent quality and supplier reliability are often more critical than initial material cost.

Daily chemical products such as detergents, shampoos, and personal care items demand chemical resistance and strong sealing.

Procurement considerations include:

Multi-layer co-extruded films help reduce packaging failure rates and customer complaints.

Agricultural films are used for seed packaging, fertilizers, mulch films, and greenhouse applications.

Buyers typically look for:

The table below provides a practical reference to help procurement teams quickly match packaging applications with typical multi-layer co-extruded film structures and key purchasing priorities.

| Application Area | Typical Film Structure | Core Performance Requirement | Primary Buyer Focus |

|---|---|---|---|

| Food Packaging | PE / EVOH / PE | Oxygen & moisture barrier | Shelf life extension |

| Pharmaceutical Packaging | PET / EVOH / PE | Moisture control & stability | Regulatory compliance |

| Daily Chemical Packaging | PE / PA / PE | Chemical resistance | Leak prevention |

| Agricultural Packaging | PE / UV Additives | Outdoor durability | Cost efficiency |

| Industrial Packaging | PE / PA / PE | Mechanical strength | Transport protection |

Even if procurement teams are not directly involved in production, understanding key control points helps evaluate supplier capability.

Precise thickness control ensures the correct balance between barrier performance and mechanical strength. Poor control often leads to weak spots and inconsistent quality.

Accurate temperature control prevents polymer degradation and improves interlayer adhesion, directly affecting film reliability.

Stable melt flow ensures uniform layer distribution and prevents delamination issues.

Advanced die systems improve layer uniformity and surface quality, especially for high-barrier structures.

Proper cooling maintains film flatness and optical clarity, reducing downstream processing issues.

Buyers sourcing multi-layer co-extruded films often face similar challenges:

To mitigate these risks, procurement teams should request sample testing, review technical documentation, and engage suppliers early in the design phase.

How do I choose the right multi-layer film structure for my product?

Start by defining barrier requirements, shelf-life targets, and packaging conditions. Then balance performance with cost by optimizing layer functions.

What factors influence the cost of multi-layer co-extruded films?

Material selection, number of layers, barrier resin usage, film thickness, and order volume all impact pricing.

Can multi-layer co-extruded films be recycled?

Recyclability depends on polymer compatibility. Many suppliers now offer recyclable or mono-material-based co-extruded structures.

Are multi-layer films always better than single-layer films?

Not always. Multi-layer films are ideal when multiple performance requirements must be met simultaneously.

Multi-layer co-extruded films represent one of the highest value-added outputs of a modern plastic sheet extruder. When designed and produced correctly, they allow manufacturers to balance barrier performance, mechanical strength, and cost efficiency while maintaining stable, large-scale production.

For procurement teams evaluating a plastic sheet extrusion line or upgrading existing equipment, it is essential to consider not only extruder capacity but also co-extrusion capability, die technology, and material compatibility. These factors directly influence film quality, waste rates, and long-term operating costs.

By treating multi-layer co-extruded films as a strategic application of plastic sheet extrusion—and by partnering with an experienced supplier like WYLONG—manufacturers can achieve reliable production, optimized material usage, and sustainable growth across food, pharmaceutical, chemical, and agricultural markets.