Thermoforming machines have long been the backbone of industries ranging from food packaging to automotive and medical devices. In 2025, manufacturers face growing demands for speed, sustainability, and customization. To stay competitive, companies must understand the latest trends and innovations in thermoforming solutions. This article explores five key market shifts, three groundbreaking technologies, and practical guidance for choosing the right machine.

2.1 Smart Automation & AI-Driven Optimization

The integration of AI and machine learning allows thermoforming machines to automatically adjust pressure, heating, and cycle times. This not only reduces defects but also maximizes uptime.

2.2 Sustainable Materials & Eco-Friendly Solutions

With stricter environmental regulations, thermoforming machines are increasingly adapted to process biodegradable and recyclable plastics, helping manufacturers reduce their carbon footprint.

2.3 Multi-Material Forming for Diverse Applications

From packaging to protective trays, demand for multi-layer and hybrid materials is rising. Thermoforming equipment now supports versatile production lines, giving manufacturers more flexibility.

2.4 High-Speed Production for Mass Customization

Consumers expect personalized products at scale. Modern machines deliver faster cycle times, enabling high-volume production without compromising quality.

2.5 Integration with Advanced Quality Control

Real-time sensors and vision inspection systems ensure consistency across batches. This reduces waste and builds customer trust in demanding sectors like medical packaging.

3.1 Adaptive Pressure Control Systems

New control systems optimize vacuum and air pressure dynamically, improving forming accuracy while reducing material stress.

3.2 Hybrid Heating Systems for Energy Savings

By combining infrared and contact heating, hybrid systems cut energy consumption by up to 20%, aligning with global energy-efficiency goals.

3.3 Modular Tooling for Rapid Configuration

Manufacturers benefit from quick-change modular tooling, reducing downtime and enabling faster shifts between product types.

4.1 Meeting Hygiene and Convenience Demands

In food packaging, hygiene is critical. Machines are now designed with easy-to-clean surfaces and streamlined workflows to meet strict food safety standards.

4.2 Sustainability in Food Packaging

Eco-conscious packaging is no longer optional. Thermoforming machines that handle compostable and recyclable films are helping food brands align with consumer expectations.

5.1 Key Considerations for Manufacturers and Suppliers

When selecting a machine, buyers should assess production speed, material compatibility, energy efficiency, and after-sales support. A well-matched system ensures long-term ROI.

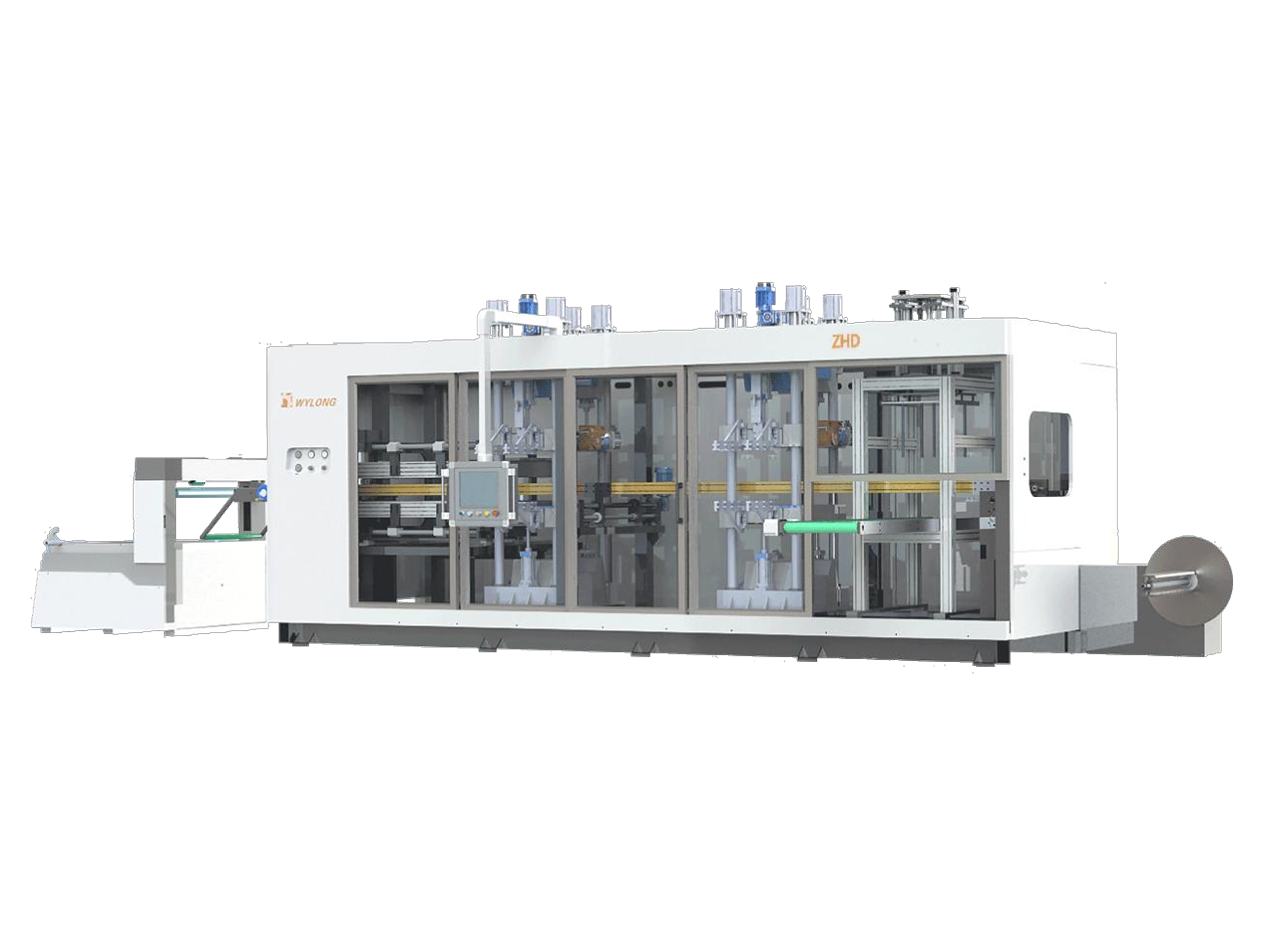

5.2 Explore Custom Thermoforming Solutions with Wylong Machinery

As a trusted manufacturer, Wylong Machinery provides tailored thermoforming solutions designed for global markets. With advanced R&D and proven expertise, Wylong helps businesses achieve efficiency, sustainability, and product excellence.

The future of thermoforming machines lies in smarter automation, greener materials, and higher efficiency. By embracing these trends and innovations, manufacturers can gain a decisive edge in 2025 and beyond. For businesses seeking reliable, custom-built equipment, Wylong Machinery stands as a partner in shaping success.